End Suction Fire Pumps are engineered to last with a precision-cast, dynamically balanced and enclosed impeller that minimizes the vibration and maximizes bearing life. Due to its back-pull-out design, the complete bearing assembly including impeller and casing cover can be dismantled without removing the volute casing from the pipe system. It can be driven by either an electric motor or diesel engine with a full range of options and accessories available to complete the NFPA-compliant fire pump. Heavy fabricated steel bases, are available to mount the pump and driver along with flexible coupling connects driver to pump. Horizontal End Suction Fire Pumps are ideal when the source of water is located above the ground as it provides a positive suction pressure to the pump at any performance point.

PUMP PERFORMANCE

- Flow ranges from 50 GPM up to 1000 GPM

- Pressure ratings from 80 psi up to 309 psi

DESIGN FEATURES

- Underwriter Laboratories (UL) – 448

- Factory Mutual (FM) – 1319

- NFPA 20

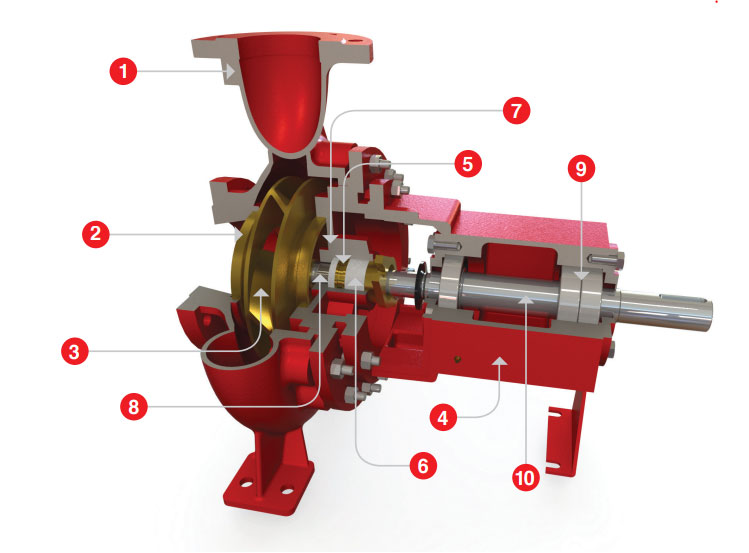

CROSS SECTIONAL

- PUMP CASING: Rugged heavy duty, volute type, centerline discharge and self-venting. Radial split design allows removal of bearing assembly and impeller without disturbing the pipe connection.

- CASING WEAR RING: Standard enclosed impellers are designed with integral case wear rings to reduce end thrust.

- IMPELLER: End suction type, enclosed, dynamically and hydraulically balanced prior to the assembly. Impellers are firmly keyed and locked to an accurately finished oversized shaft to absorb all shock loads.

- BEARING HOUSE: both the inboard and outboard bearing are protected by lip seals to keep contaminants out of bearing.

- LANTERN RING: A perforated hollow ring that receives relatively cool, clean liquid. Distribute uniformly around the shaft to provide lubrication and cooling.

- GLAND PACKING: flexibility allows the shaft to run freely as well as leak proof.

- CASING COVER: Accommodate with square rings of packing with a lantern ring. Stuffing box is completely removable and replaceable with rotating assembly.

- SHAFT SLEEVE: Easy to replace centrifugally cast sleeves protect the shaft from packing wear and are sealed to prevent leakage. Sleeves are accurately positioned and licked in place.

- BEARING: Cartridge mounting, maintains impeller in their central position, grease type lubrication standard.

- SHAFT: High strength steel, grounded and polished to a smooth surface, design to transmit full driver horsepower with a liberal safety factor and minimum deflection.